Noatex has been operating since November 2017, offering the most demanding customers a highly professional, CSR compliant and technically advanced bag manufacturing facility in a developing country with very competitive wages and abundant hard working operators. Our motto is: continual improvement and customer satisfaction.

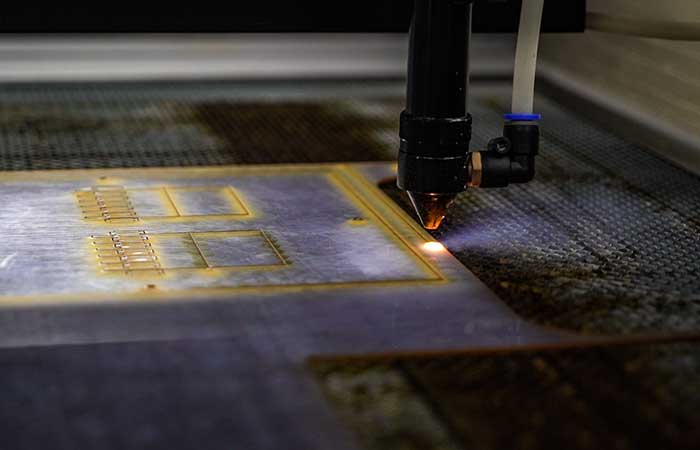

Technology

- Advanced electronic sewing machines

- 30 computerized pattern sewing machines

- Sublimation and high frequency

- Laser cutting Computerized pattern making

- Professional Western production management

- Production engineering department focused on developing tailor made innovative manufacturing solutions for each product.

Quality

- Strong team of QA and QC staff

- Documented incoming material inspection (IQC)

- Sublimation and high frequency

- In-process quality control (IPQC)

- Finished goods quality control (FQC) - All finished products inspected by our QC team according to AQL standard

R&D

Noatex customers will be able to enjoy both worlds - the low cost of production in developing Myanmar and the 20 years experience in advanced bag and sewn product development and production of the Starry Group.

Why Myanmar?

- Due to the GSP, Myanmar has duty-free import into the USA and Europe for travel goods

- Very competitive labor cost. Competing production locations primarily China and Vietnam have higher labor costs and labor shortages

- Myanmar is a developing nation of 50 million people with substantial manpower reserves

Our obligation is to meet our customers capacity needs with a diversified sourcing solution and uncompromised quality